Efficient air humidification with high-pressure humidification systems

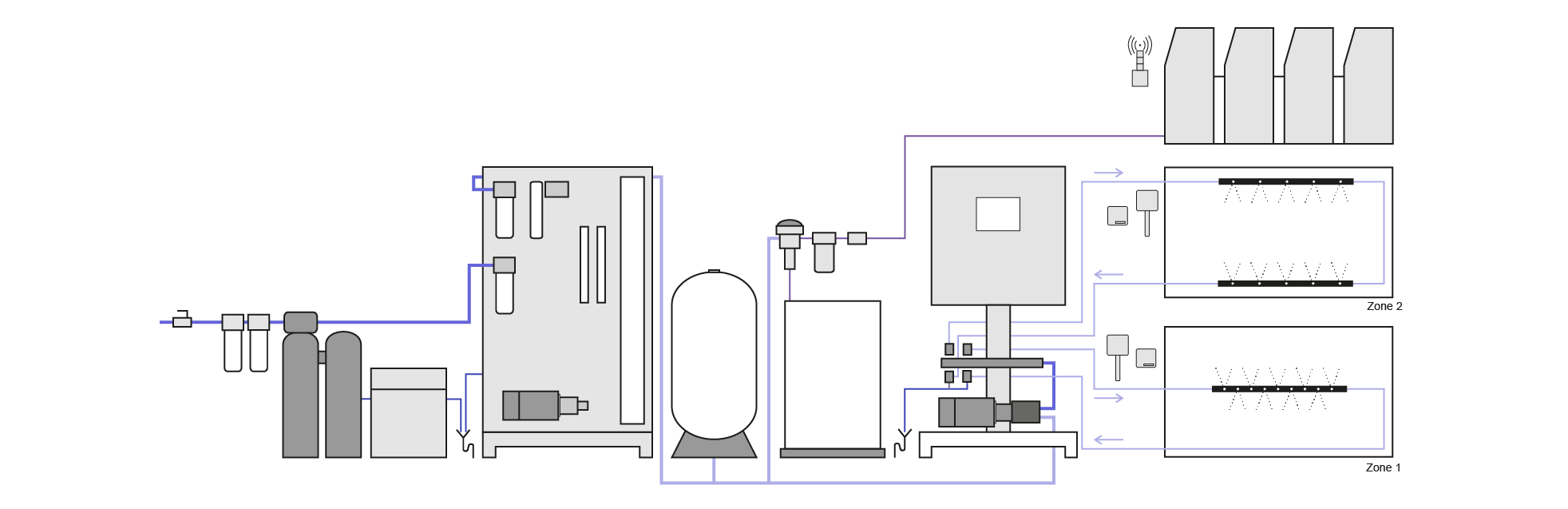

FINESTFOG humidification systems atomise water into very fine aerosols that are quickly absorbed by the air. The perfect interplay of the patented high-pressure nozzles and the consistently high water pressure allow precise humidification for almost any room size and application. In combination with a FINESTFOG water treatment system, hygienically perfect pure water is used. Up to 10 rooms can be humidified fully automatically with one central system. The humidity in the room is measured. The humidity and temperature are displayed on the large illuminated display in the room.

Are FINESTFOG humidification systems suitable for rooms with low ceilings?

Yes. FINESTFOG high-pressure nozzles are available in six different power ranges. Nozzle 1.0 is used in low-ceiling rooms. It atomises a maximum of 1.1 litres of water per hour of continuous operation. The aerosols are so fine that it does not precipitate even at low-ceiling room heights. The optional joint helps to direct the spray cone in the desired direction.

How does FINESTFOG guarantee the highest standards of hygiene in air humidification?

The air humidification and water treatment is a completely closed system. The water only comes into contact with the ambient air after atomisation. A periodic hygiene flush (variably adjustable) prevents water from standing in the pipes for too long. Every pipe and every single nozzle is flushed. The integrated UVC irradiation and the maintenance contract including water samples round off FINESTFOG’s unique hygiene concept.

The nozzle - the centrepiece of FINESTFOG high-pressure air humidification

The FINESTFOG single-fluid nozzle is the centrepiece of every FINESTFOG humidification system. This patented, high-quality stainless steel nozzle is developed and manufactured exclusively for our humidification systems, which is guaranteed by the FINESTFOG engraving on each nozzle. The nozzle insert, combined with a special bore and a final, hand-finished finish, gives it a unique atomisation pattern: The water is atomised into extremely fine aerosols that can be quickly and efficiently absorbed by the air.

In addition, a non-return spring ensures that no water drips, which further increases the efficiency and reliability of our humidification systems.

FINESTFOG nozzles are available in six sizes

| Model | Bore | Humidification performance: Liters / hour. |

|---|---|---|

| 1.0 | 100 µm | 1,1 |

| 1.5 | 150 µm | 2,0 |

| 2.0 | 200 µm | 3,0 |

| 2.2 | 220 µm | 4,6 |

| 2.5 | 250 µm | 6,3 |

| 2.7 | 270 µm | 8,4 |

Adaptation to any room size

Nozzle 1.0 is mainly used for low-ceiling room heights and in small rooms. The models 1.5 and 2.0 atomise in almost all areas, and the models 2.2, 2.5 and 2.7 with their high humidification performance are the ideal nozzles for adiabatic cooling and for high humidification performance in duct humidification.

Ultra-fine atomisation

The ultra-fine atomisation in FINESTFOG nozzles replaces the use of fans or even compressed air. The nozzles are screwed directly into a discreet but solid 1/8″ stainless steel pipe. An optional swivel joint (see image) increases flexibility. The pipes can be easily mounted on the wall, under the ceiling, on cable trays, on glue laminated beams or on double T-beams. This easy installation option is also used in humidification chambers.

Almost noiseless

FINESTFOG nozzles atomise almost silently and almost invisibly – nothing stands in the way of their use in offices or living rooms.

Maximum control & efficiency: System control for FINESTFOG humidification systems

At FINESTFOG, we place particular emphasis on the high-quality control of our humidification systems. We only use components from well-known manufacturers such as Siemens or Eaton to guarantee the quality and reliability of our systems. Our humidification systems are available with two types of controls:

System control with Eaton E4

Eaton E4 – the controller for fully automatic control of up to 6 humidifier zones and a humidification performance of 60 to 840 litres per hour. Equipped with Eaton PLC, 7″ touch display and frequency converter. Among other things, the control unit is equipped with a data logger, an operating hours counter per zone, a trend analysis and numerous additional functions. From data transfer to a BMS to remote monitoring, many things are possible. Ask our specialists about the configuration variants.

System control with Siemens S 7

Siemens S7 – equipped with a Siemens PLC. Up to 10 zones can be humidified fully automatically. The SIMATIC HMI KP 700 touch panel (size 7″) displays all operating parameters. Among other things, the control unit is equipped with a data logger, an operating hours counter per zone, a trend analysis and numerous additional functions. From data transfer to a BMS to remote monitoring, many things are possible. Ask our specialists about the configuration variants.

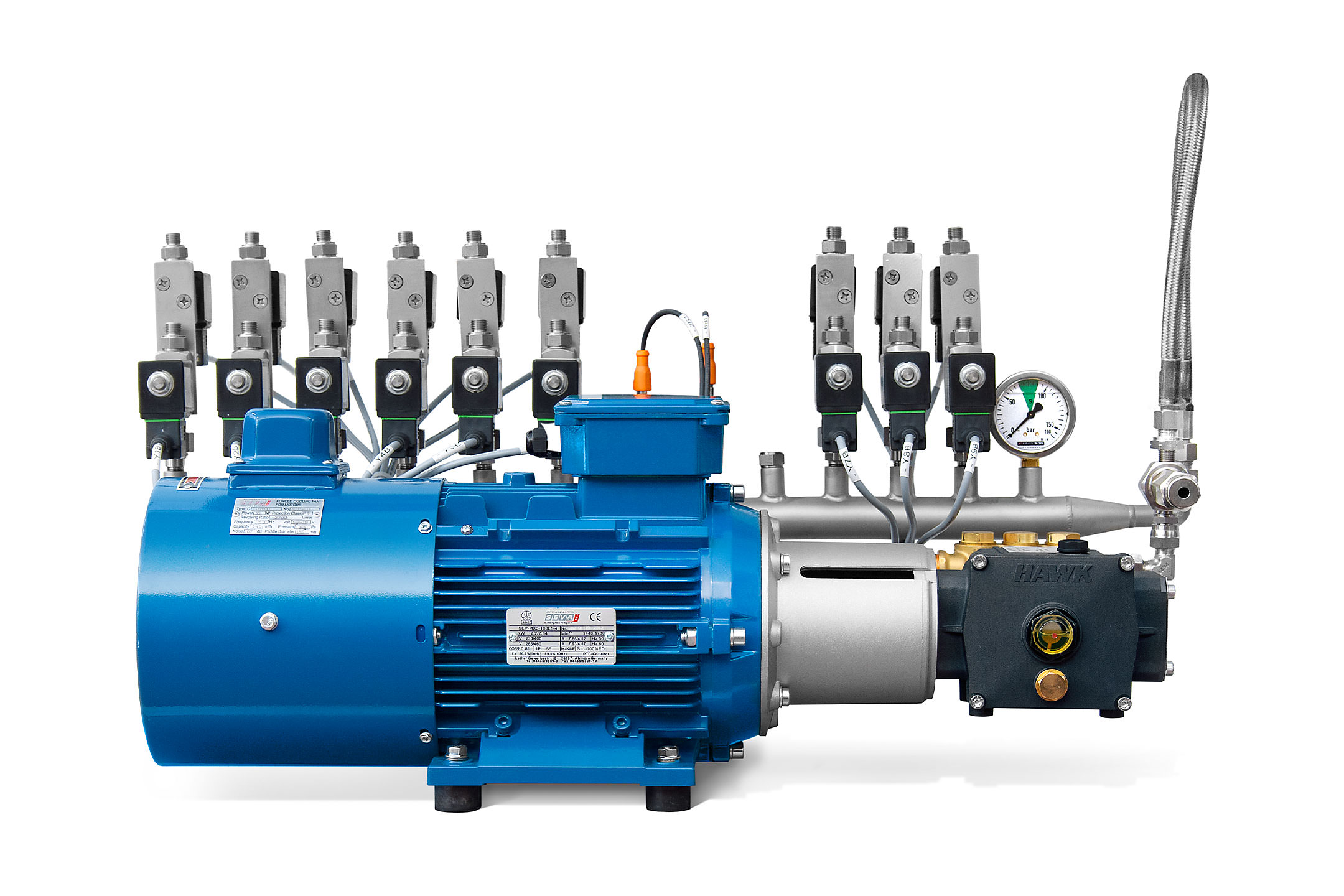

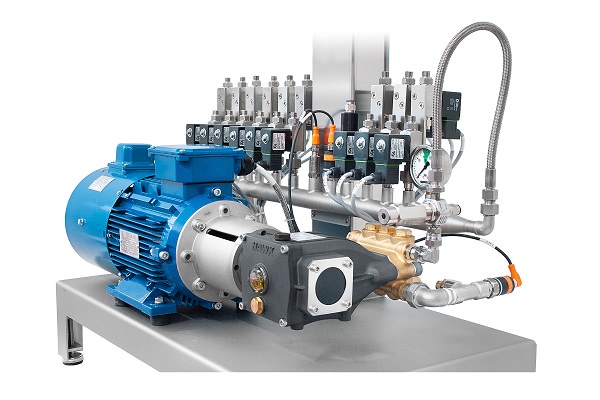

Powerful high-pressure pumps for optimum air humidification

The high-pressure pump generates an even pressure (70 bar) and supplies the individual zones with pressurised water. The pumps are available in capacities from 60 to 840 litres per hour. The speed of the motor and the pump is controlled via the pressure sensor and the frequency converter. The pump only pumps as much water as is currently required. This saves energy and protects the pump.

Frequency-controlled pump

The pressure sensor always generates a pressure of 70 bar. Regardless of whether one, two or ten zones are in operation. As much water is pressurised as is needed at any one time. This saves energy and minimises wear on the pump.

Distributor with stainless steel solenoid valves

The high-pressure pump is connected to the distribution pipe. In addition to the water inlet pressure monitoring, the pressure sensor and the pressure gauge, the stainless steel solenoid valve sets are also installed there. Each zone contains 2 solenoid valves. One opens the humidification zone. The second ensures pressure relief, prevents the nozzles from dripping and enables periodic hygiene flushing.

Frequently asked questions (FAQ)

Do humidifiers have to be labelled with a hygiene certificate?

If it is the right certificate, then yes. FINESTFOG are certified by the German Statutory Accident Insurance. This certificate was developed together with the employers’ liability insurance associations. The certificate: “Optimised air humidification” focuses on technology and hygiene. The certificate is not a snapshot, as it has to be “re-certified” every few years and regular hygiene tests are carried out on the operators’ premises by the testing centre.

FINESTFOG air humidification and water treatment can be certified in accordance with VDI 6022 on request. An independent RLQ manager assesses the system, the installation situation and the system documentation. The operating personnel are also assessed. The operator’s technical personnel must be qualified to carry out a service on a FINESTFOG system, for example.

Why do FINESTFOG systems always humidify without fans?

Because fans cause electricity costs, become very dirty due to dust and moisture and there is no safety in the event of a malfunctioning fan. In addition, the running noise of the fans is surprisingly high.

FINESTFOG nozzles are positioned in such a way that no precipitation occurs. Thanks to the extremely fine atomisation, no supporting air is required. It is also not necessary to cycle the nozzles. And physics takes care of the distribution of humidity in the room thanks to adiabatic cooling and changes in the density of humid air. So save electricity and service costs and use FINESTFOG nozzles without fans.