High-pressure water mist technology for industrial air humidification

Increase productivity, minimise waste. Healthy indoor climate for production. FINESTFOG high-pressure air humidifiers for industry offer all of this. With little effort, optimum humidity is achieved. The size of the room and the number of rooms are irrelevant. Thanks to various nozzle and pump sizes, almost any room volume can be humidified. In addition, a healthy indoor climate can be ensured fully automatically in up to 10 rooms. The humidity and temperature reached in each room is indicated on the sensor’s illuminated display. As an alternative to direct room humidification, humidification can also be provided via central ventilation systems. This solution is of interest for many small rooms with high air exchange rates that are supplied via a central ventilation system.

What characterises our air humidification systems for industry?

Creating exact climate setpoints

FINESTFOG duct humidifiers for industrial use operate with control accuracy. The control with integrated Siemens PLC and clear touchscreen receives the control signal, converts it into a seven-stage cascade circuit and doses the humidification in the HVAC system. There, the patented FINESTFOG high-pressure nozzles atomise the water into a very fine mist without dripping. Their different outlet sizes adapt the humidification to every requirement. This ensures that the desired humidity is achieved precisely. This is cost-effective, energy-optimised and precise air humidification for industry.

Reducing maintenance effort/costs

Air humidification in industry must be possible without the need for a large number of personnel. Conventional air washers do not fulfil this requirement. They circulate the water that has not evaporated again and again – with all the drawbacks for hygiene: Chemical additives, complex UV disinfection and very high maintenance requirements. These systems also require an unnecessarily large amount of water, as the water in the pool has to be replaced regularly. FINESTFOG channel humidification for industry keeps the proportion of waste water low, and only fresh, ultra pure water from the FINESTFOG reverse osmosis system is used. The periodic rinsing cycle, integrated UV disinfection and regular maintenance by qualified FINESTFOG technicians round off the hygiene concept of FINESTFOG duct humidification. Your industrial company can “breathe a sigh of relief” and devote itself to the important issues.

Minimising energy consumption

Steam air humidifiers are known for their high energy requirements. However, air washers also have a high power consumption due to the circulation pumps required. These are all hidden costs for an industrial company. FINESTFOG air humidification saves energy: frequency-controlled pumps, cascade configuration and high efficiency significantly reduce energy costs compared to other systems.

Achieving hygiene safety

FINESTFOG high-pressure air humidification for use on HVAC systems is VDE and CE approved. It complies with VDI 6022 Sheet 1 and Sheet 6 and has held a recognised hygiene certificate from the GBA Hamburg since 2004. FINESTFOG duct humidifiers for industry correspond to FINESTFOG direct room air humidifiers, which possess the “Optimised air humidification” test certificate and the “GS test mark” and are certified by the DGUV and BG ETEM.

Air humidification in the wood industry

Wood is a hygroscopic natural raw material whose processing is influenced by the ambient air. The lower the air humidity, the more the wood moisture content decreases. If the relative humidity falls below a value of 50 %, wood reacts with shrinkage, cracking and warping. Veneer and particle board in particular are at risk, but even solid wood is not unharmed.

Smooth processing of the natural material can be achieved technically by humidifying the air. By constantly setting the humidity to a controlled value, FINESTFOG air humidification adapts the wood to the processing requirements. In addition to production, a constant humidity of 50 – 60 % RH is also required in the timber store and even during timber drying.

In addition, healthy humidity reduces dust pollution and improves the quality of the air we breathe.

Extract from references

- Rubner Holding, South Tyrol (I)

- WIEHAG GmbH, Altheim (A)

- Rettenmeier Holzindustrie, Hirschberg (D)

- EgoKiefer AG, Altstätten (CH)

- Steinway & Sons, Hamburg (D)

- Knaus Tabbert, Jandelsbrunn (D)

- Prüm Türenwerke, Weinsheim (D)

- Rekord Fenster- und Türenwerke, Dägeling (D)

Air humidification in the paper industry

Print shops and the paper industry use FINESTFOG air humidification to control the properties of hygroscopic paper. Insufficient humidity causes rippling, shrinkage and registration problems. FINESTFOG achieves precise humidity, reduces waste, electrostatic charge and machine stops, while fine dust and high temperatures are reduced through adiabatic cooling.

Manufacturers of digital printing machines require a humidity of 40-60% RH. Without air humidification, values are often below 30% RH. FINESTFOG is not only advantageous in the production area, but also in the CTP area, paper warehouses and offices.

FINESTFOG water treatment supplies the air humidification system with pure water and at the same time flows into the fountain solution supply of the printing presses, ensuring efficient and safe use in the paper and printing industry.

Extract from references

- Aumüller Druck, Regensburg (D)

- Elanders Print & Packaging (D)

- WestRock Gruppe (D-CAN-USA)

- Carl Edelmann GmbH (D)

- Graphic Packaging Munich GmbH (D)

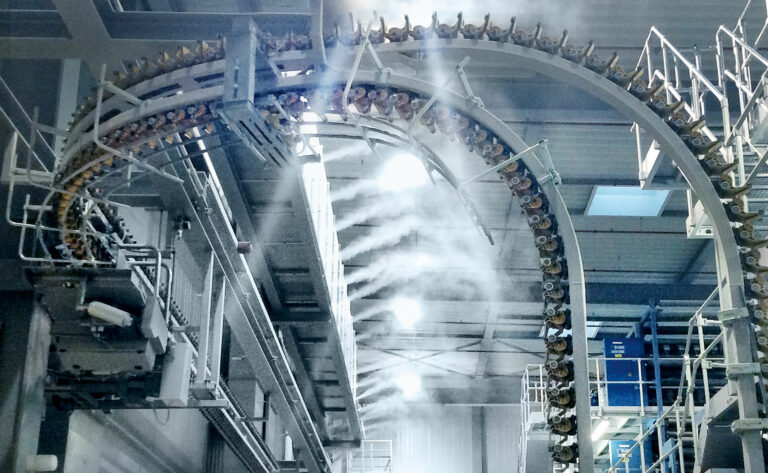

Air humidification in the textile industry

Natural humidity is not sufficient in the textile industry. Especially during the heating period, the values often drop to below 30% relative humidity. Depending on the production process, textiles require significantly higher moisture values:

Cotton, wool, silk, rayon and synthetic fibres require between 60 and 75% relative humidity when weaving, carding or spinning.

The higher humidity increases the weight of the material and makes it easier to process. The electrostatic charge is also reduced. The air becomes more conductive due to the higher water content of the air. Charges are diverted and do not remain on the guide eyes, machines or materials, for example. Thread breaks and size changes around material are prevented.

Extract from references

- Medi, Bayreuth (D)

- Falke, Zwörnitz (D)

- Tenovo, Hof (D)

- Conzelmann, Albstadt (D)

- Bauerfeind, Zeulenroda (D)

- Erzi Flock, Reutlingen (D)

- Zwickauer Kammgarn, Wilkau (D)

Air humidification in the electronics industry

In the electronics industry, humidity control is essential to prevent electrostatic discharge (ESD) and protect electronic components. FINESTFOG offers efficient air humidification solutions that not only increase productivity, but also protect employees and products.

Low humidity (below 30%) increases the risk of ESD. FINESTFOG systems increase the air humidity to 40% to 50% in order to improve the conductivity of the air and safely dissipate electrical charges. This method is particularly effective in ESD protection and contributes to the comprehensive protection of electronic components.

In addition, FINESTFOG’s optimised air humidification ensures that machines produce at high speed without any loss of quality. At the same time, the amount of fine dust particles in the air is reduced. At ideal humidity levels, dust particles bind together, become heavier and can be removed more effectively by ventilation systems.

Selected refrences

- TQ-Systems, Peiting (D) Zollner Elektronik AG

- Werke in Zandt; Altenmarkt, Untergschwandt und Furth im Wald (D)

- Becom Electronics, Werke in Hochstraß (A) und Környe (HU)

- Neways Neunkirchen GmbH (D)

- Wenglor Sensoric GmbH; Tettnang (D)

- Fronius International GmbH; Sattledt (A)

Frequently asked questions (FAQ)

In which areas are Finestfog air humidifiers used?

FINESTFOG air humidifiers are used wherever hygroscopic materials are processed. Mainly in areas where paper, wood and textiles are processed. As electrostatic charges are significantly reduced by humidifying the air, FINESTFOG air humidifiers also help in the electronics industry, in the automotive industry and wherever paint is applied. Thanks to the healthier climate provided by air humidification, FINESTFOG systems are used in theatres, open-plan offices, call centres and other comfort areas. High humidity is also used in botanical gardens, zoological gardens and in plant cultivation.

What is the difference between room air humidification and duct air humidification?

FINESTFOG direct room humidification humidifies directly in the desired rooms without any detours. A centralised system ensures precise, healthy humidity in up to 10 different rooms / areas fully automatically.

Humidification can also be provided by a central ventilation system, which supplies the rooms with fresh and recirculated air. This air is pressurised with moisture in a “humidification chamber”.

FINESTFOG air humidifiers can be used in the room or in central ventilation systems. Which application makes the most sense is decided individually after an on-site consultation.

How does the installation process work?

From the manufacturer to the operator, everything from a single source – this also applies to the installation of FINESTFOG systems. All air humidifiers and water treatment systems are installed by qualified FINESTFOG technicians. Maintenance, service and support are also carried out by our own team. FINESTFOG technicians are also trained and qualified to take water samples from the systems.

Are care and support guaranteed?

Our FINESTFOG technicians are deployed throughout Germany to support operators. In addition, our team, which provides telephone support, is also based at our headquarters in Ottobrunn. Spare parts can be dispatched overnight on request.

Is there any production downtimes during installation?

Generally no. Nozzles are often installed in driveways and never above machines. Our technicians take production processes into consideration. If necessary, installation can also be carried out at night, at weekends or during company holidays.