Process-accurate room humidity - energy-efficient and environmentally-friendly

With our FINESTFOG room humidification for industry, we offer energy-saving and hygienically perfect high-pressure humidification that does not require fans or compressed air. Our patented FINESTFOG high-pressure nozzles humidify rooms of any volume discreetly and almost silently. Well over 2,000 FINESTFOG systems are now producing an optimum climate for people and materials in production, event and office spaces throughout Germany, Europe and the rest of the world.

Advantages of our industrial room humidification systems

Increased production quality

Material shrinkage, loss of quality or electrostatic charging – resulting in machine downtime or high levels of rejects – are signs of low humidity. Particularly in winter, heating and dry fresh air also reduce the values to a worrying level.

FINESTFOG room humidification keeps the air humidity constant at around 50 % r.h. Electrostatic charge is reduced. Hygroscopic materials such as wood, paper and textiles can be processed more easily and precisely.

Economical and energy-efficient air humidification

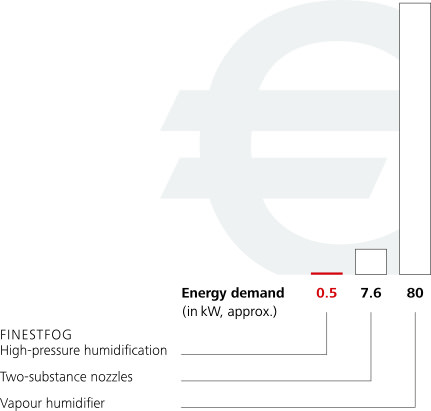

FINESTFOG room humidification uses high pressure (70-80 bar) to atomise water into extremely fine aerosols that are quickly absorbed by the air. The energy requirement is limited to the motor power of the high-pressure pumps and is extremely low: It is between just 0.5 and 4.0 kW per hour of continuous operation, depending on the humidification capacity and pump size. All motors are speed-controlled thanks to the integrated frequency converter and only produce as much pressurised water as is needed at any given moment. This also saves energy and protects the pumps.

Neither compressed air nor fans are required to atomise the water into extremely fine aerosols. FINESTFOG requires around 1 KW of energy to atomise 100 litres of water. In comparison, a system atomising with compressed air requires approx. 9 KW and a steam air humidifier as much as 85 KW.

If high-pressure air humidification is also used to cool the ambient air, a lot more energy can be saved. This way, cooling systems can be effectively supported and large amounts of energy can be saved at peak load times.

In certain cases, adiabatic cooling can even replace conventional air conditioning.

Cooling the room air

Humidifying at high pressure also means cooling at the same time; and with the least amount of energy. Because adiabatic cooling utilises nature: Water changes its physical state through atomisation. It needs energy to do this – energy that it extracts from the air: The air cools down. FINESTFOG systems are used to reduce temperature peaks. In heat-intensive production areas, the temperature reduction can be up to 5 °C. FINESTFOG air humidification supplements a conventional air conditioning system and can even replace it in certain applications.

Reduced sick leave

Tiredness, lack of concentration, dry mucous membranes, a weakened immune system – dry indoor air makes you ill. FINESTFOG air humidifiers ensure a healthy humidity level (50% r.f.) and bind fine dust in the air. A controlled indoor climate is essential not only in production areas, but also in offices, conference rooms and showrooms. Occupational health and safety regulations are therefore complied with. Air humidification from FINESTFOG is VDE and CE-tested and complies with VDI 6022. FINESTFOG high-pressure air humidification is certified: it has a recognised hygiene certificate from the German Statutory Accident Insurance (DGUV) and the employers’ liability insurance associations. The “optimised air humidification” and “tested safety, GS” certificates document the state of the art for the best possible hygiene safety. VDI 6022 certification of FINESTFOG air humidification at the owner’s premises is also possible on request.

Neither compressed air nor fans are required to atomise the water into extremely fine aerosols. FINESTFOG requires around 1 KW of energy to atomise 100 litres of water. In comparison, a system atomising with compressed air requires approx. 9 KW and a steam air humidifier as much as 85 KW.

If high-pressure air humidification is also used to cool the ambient air, a lot more energy can be saved. This way, cooling systems can be effectively supported and large amounts of energy can be saved at peak load times.

In certain cases, adiabatic cooling can even replace conventional air conditioning.

Energy saving at Hipp Fensterbau

Energy saved: 5 kWh

Hipp Fensterbau

Hipp Fensterbau GmbH & Co KG in Trochtelfingen has replaced 10 nozzles atomising with compressed air with 14 high-pressure nozzles from FINESTFOG. Fully automatic, energy-saving humidification is now used in two painting areas. Instead of around 5.5 KW, only 0.25 KW of electricity per hour of operation is now required.

Energy savings at Holz Schiller GmbH

Energy saved: 28 KW/h

Holz Schiller GmbH

The first FINESTFOG air humidifiers were installed at Holz Schiller GmbH in Regen back in 2008. Instead of using dual-fluid nozzles with an energy consumption of 30 KW per hour of operation, 110 high-pressure nozzles have been used for humidification since 2008. The energy requirement for FINESTFOG high-pressure air humidification is just under 2 KW per hour of operation.

Frequently asked questions (FAQ)

What is the difference between FINESTFOG high-pressure air humidifiers, dual-fluid nozzles and steam air humidifiers?

Steam air humidifiers are very energy-intensive and are therefore hardly ever used in rooms. The maintenance effort is also considerable. Dual-fluid nozzles atomise the water into aerosols with the aid of compressed air. Compressed air atomising nozzles are loud and cannot be used in comfort areas. The energy requirement is significantly higher than for high-pressure air humidifiers due to the use of compressed air. High humidification capacities require an enormous compressor power.

FINESTFOG high-pressure air humidifiers, on the other hand, are energy-saving, quiet and efficient, making them the ideal choice for industrial room humidification.

What type of water quality is required for FINESTFOG room humidification systems?

FINESTFOG room humidification systems should be supplied with pure water from a reverse osmosis system. This prevents clogging of the nozzles and mineral deposits in the room.

The reverse osmosis system produces almost germ-free and salt-free water for air humidification. FINESTFOG provides the appropriate water treatment in every size.

What differentiates direct room humidification from indirect air humidification via supply air systems?

Direct room humidification is more effective. 100% of the used clean water is evaporated. Each room is humidified individually. In supply air systems, it must be taken into account that a portion of the clean water always flows into the drain as loss water. In addition, the inlet temperature of the supply air must be significantly heated before humidification to compensate for the adiabatic cooling in the humidifier chamber. As a result, the energy consumption is generally higher than in direct room humidification. The effect of adiabatic cooling in the room is eliminated when humidifying via the central ventilation system.

How quickly does the air humidity regulate after the operation of a FINESTFOG room humidification system?

As FINESTFOG’s specialist consultants calculate the exact humidification capacity required when preparing the quotation, the humidification capacity is designed to achieve the ideal humidity level within a short period of time.

Thanks to the high-precision moisture sensor, this all works fully automatically. The values can be read off the control centre or the humidity sensor.

Can FINESTFOG room humidification systems be integrated into existing ventilation or air conditioning systems?

The basic technology for room humidification systems and ventilation or air conditioning systems is the same. However, the control and especially the installation of the nozzles differ significantly.

The choice of technology often depends on the spatial conditions or the construction of the ventilation centres. FINESTFOG consultants can objectively assess which FINESTFOG solution is more cost-effective for the operator.

Up to 90% energy savings with FINESTFOG high-pressure single-fluid nozzles

FINESTFOG single-fluid nozzles atomize pure water at high pressure without any carrier air, eliminating the need for expensive compressed air compression, fans, or other aids.

For comparison: To atomise 100 litres of water per hour, a FINESTFOG high-pressure system requires only about 1 kW of motor power. Dual-fluid nozzles consume around 9 kW for the same humidification output, and a steam air humidifier even consumes around 85 kW.